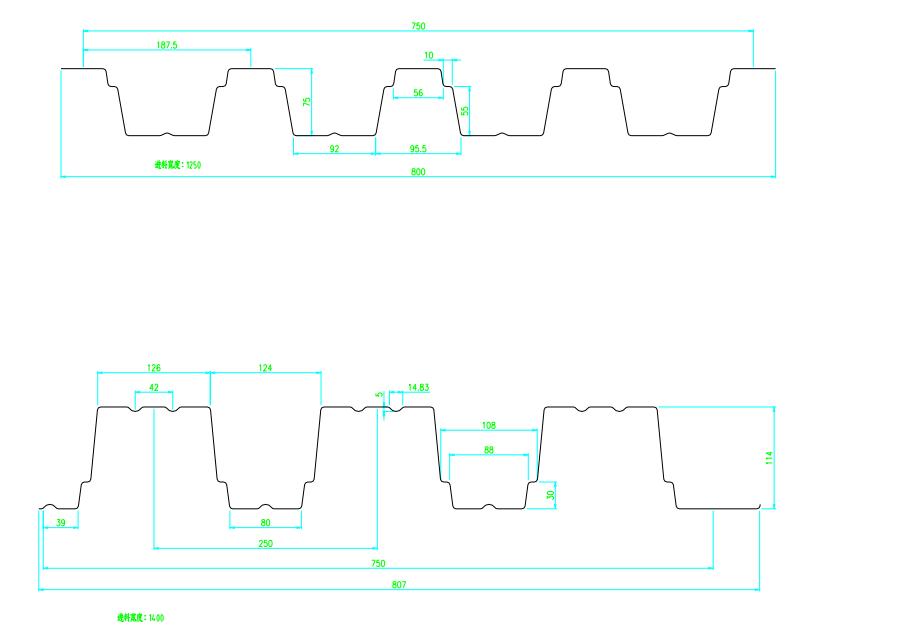

Customer drawing profile: material thickness Max to 1.2mm

Here is the finished product pictures for your reference:

Metal decking machine for Albania pictures for your reference:

|

|||

| Technical parameters | |||

| Main elements | manual decoiler, guiding platform,main machine of roll forming, cutting device, electric motor,hydraulic station, PLC control system, run out table | ||

| Material | Raw material | S350 & S450 grade steel or galvanized coil | |

| Thickness | 0.5-1.2mm | ||

| Hydraulic Decoiler |

Inner Diameter:450-550mm | Expand by hydraulic | |

| Outer Diameter: max 1500mm | |||

| Max Coil width:1250mm | |||

| Capacity: 5T | |||

| Leveling beach With the embossing roller |

For making coil neat and clean from decoiler, coil will be a little curve. Meanwhile for saving coil, we will give motor shearing system to cut coil at any part. The embossing roller shaft diameter=120mm. |

||

| Logo Punching | If you need we can add this function for you. | ||

| Main Forming machine |

Forming steps | 34 roller stations | |

| Rolling method: for rolling methods, we use the separated molds rolling forming. | |||

| Shaft diameter | 90mm, the embossing roller=120mm | ||

| Diameter | 90mm | ||

| Design type | Middle plate welded | ||

| Machine frame thickness | 20mm | ||

| Machine frame | 400# H steel welded | ||

| roller material | 45# steel, surface hard chromium plating. | ||

| shaft material | 45# steel adjusting the density | ||

| Work speed including shearing |

8-12m/min | ||

| Transport | By chains of 1.25mm | ||

| Power of main machine |

18.5 kw two motors to give the power more evenly to the machine | ||

| Shearing system | Type of cutting power | Hydraulic | |

| Elements | Two hydraulic jacks for fast shearing speed | ||

| Frame | Pillar pole type to make sure working steady | ||

| Cutting blade material | Gcr12, queening at 58 to 62 degree to make sure hardness and long time to use. | ||

| Cutting tolerance | ±1mm | ||

| Cutter blade more pair | We will give one more as spare part | ||

| Cutter quantity | 2 set | ||

| Working pressure | 20 MPA | ||

| Motor Brand | Siemens | ||

More details of the machine pictures for your reference:

We have installed the punching station on the machine, then it is quite easier for installation. We also added the punching logo this machine.

For the leveling part, we add the mold protector holder and the brake for easy to feed coil and also have the good embossing effect.

For the metal decking machine, we have made more types, here are more drawing profiles for your reference. If you need to know more information,please contact us at any time.

اللغة العربية

اللغة العربية