Light Gauge Steel Framing Machine Technical Specification:

Width(web): 89mmHeight(flange): 41mm

Lip:7-12mm The machine match with 3 sets punching die(75~96/138-159/180-200)mm

Material Thickness:0.75-1.2mm,Q235、Q345、G550, hot-rolled galvanized steel strip

Speed: 48m/min

Revised Product Overview: C89 LGS Framing System for Prefabricated Villa Construction

Material: Zinc-coated steel coils

Thickness Capacity: 0.5-0.9mm

Line Speed: 25-30 meters/minute

Power Requirement: 5.5kW main drive

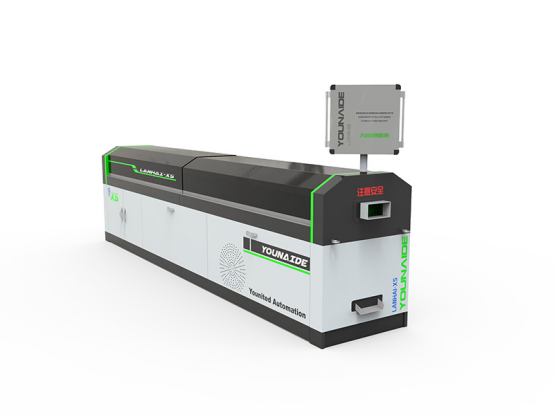

Dimensions: 6000×700×800mm (L×W×H)

Advanced Manufacturing System:

This automated fabrication system integrates precision component production with intelligent building design solutions, specifically engineered for prefabricated light steel structure (LSS) construction. The equipment combines cutting-edge servo drives, hydraulic power units, digital control interfaces, and thermal management components to achieve high-speed precision forming.Operational Workflow:

1. Coil loading station2. Automated material feeding

3. Progressive roll forming

4. Programmable cutting unit

5. Finished product output

Key Performance Features:

• Enhanced Production Efficiency: Achieves 300-900 linear meters/hour throughput with optimized mold design

• Precision Engineering: ±0.5mm dimensional tolerance maintained through SKD11 tooling (3M+ cycle durability)

• Intelligent Operation: Touchscreen HMI with CAD/CAM integration for automated drawing interpretation

• Modular Design: Quick-change die sets support multiple functions including perforation, chamfering, and edge trimming

• Energy-efficient Operation: 12-stage forming process with thermal regulation extends equipment lifespan

Structural Advantages:

- Dual reinforcement technology for enhanced load-bearing capacity

- Interlocking vertical/horizontal member compatibility

- Universal accessory compatibility across building systems

- Surface protection maintains material integrity during processing

Compliance & Applications:

Certified to meet Australian/New Zealand building codes (AS/NZS 4600) for cold-formed steel structures. Ideal for:

• Prefabricated residential units

• Modular commercial complexes

• Temporary emergency shelters

• Agricultural facilities

• Hospitality infrastructure

Technical Support Package:

• Comprehensive 12-month warranty

• On-site commissioning services

• Architectural design consultation

• Operator training programs

• Lifetime maintenance support

This innovative fabrication solution represents the next generation of construction automation, combining material efficiency with digital manufacturing technologies to revolutionize light steel structure production.

اللغة العربية

اللغة العربية