Downpipe gutter pipe rolling forming machine

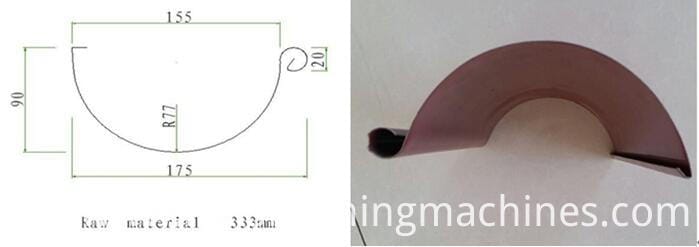

The function of the downpipe Roll Forming Machine is to collect rainwater from the roof is part of the water fall system and is concentrated in the rainwater pipe laid below the ground. Take the following half round gutter pipe drawing for example to show how the gutter pipe machine is composed:

The machine is composed by Manual Decoiler, leveling beach, roll forming machine, shearing system and runout out table, PLC control sysyem, and hydraulic system.

1-Manual decoiler

Feeding type: Automatic feeding

Structure: Cantilever

2-Entry Beach

Put the raw material (steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity.

3-Main gutter pipe forming machine

Frame: Longmen wallboard type

The roller number: 18 rollers

Roller material: Cr12

Shaft diameter: 60mm, 45# steel

Roller heat treatment: Quenching, HRC58-62

Material thickness: 1.5 mm to 2.0 mm

The standard cutting size: 198 mm (According to customer request design of blade shape)

Voltage: 380V/50HZ/3Phase (As customer`s request)

4-Hydraulic cutting

Cutting type:Hydraulic cutting Blade material: Cr12MoV

Blade quantity: 1 set Cutting frame: 1 set

Mould material: Cr12MoV Motor power: 3 kw

5-Products receiving table

It adopts welded steel and supported roller to transmit the products.

Table length : 1.5m/per set

Table quantity: 1 sets

Where the gutter pipes will be used:

Looking for ideal Downpipe Rolling Forming Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Gutter Pipe Forming Machine are quality guaranteed. We are China Origin Factory of Gutter Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Gutter & Downspount

Mr. Cary xu

Mr. Cary xu