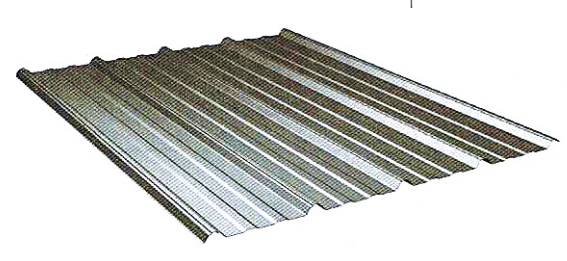

Steel Sheet Roof Panel Roll Forming Machine Effective Width 1100

We have rich experience in making Wall and Roof Roll Forming Machine. And this Roof Roll Forming Machine can make the roof product with effective width 1100. It is durable and more popular. You can check its profile in the following.

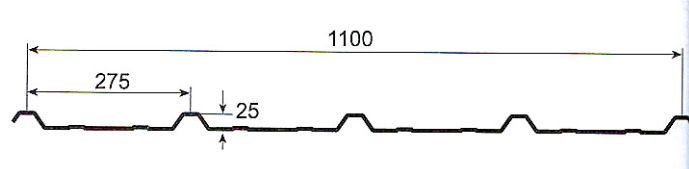

product drawing

| Main Parameters |

| Length of the main part | 7200*1650*1500 mm |

| Weight of main part | 4.5 t |

| Voltage | 380V/50HZ 3Phase(as customer`s request) |

| Roller fixer | Middle plate welded |

| Frame | 350 H steel welded |

| Frame thickness | 25 mm |

| Drive mode | Chain |

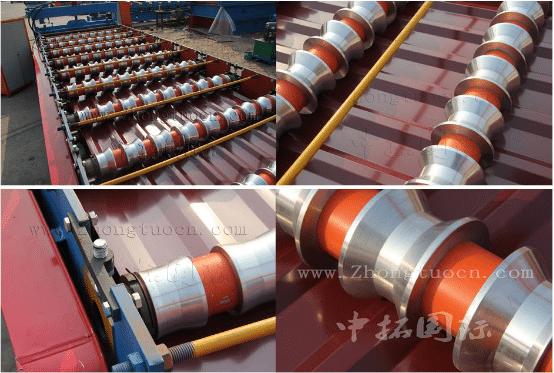

| Material of rollers | 45# steel,surface hard chromium plating |

| Material of shafts | 45# steel |

| Diameter of shafts | Φ80 mm |

| Number of rollers | 11 rollers |

| Main power | 3 kw |

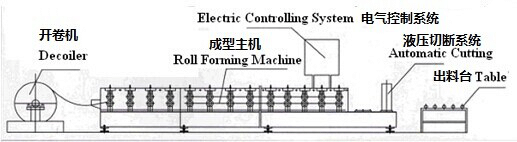

Production process of 1100 steel Roofing Sheet Rolls Forming Machines

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Step formed→ Auto cutting→Products receiving

Decoiler(Hydraulic Uncoiler or Manual Decoiler)

Function: Supporting and uncoiling the steel strips

Roll Forming Machine

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Feature : Ensure stability , precision and lifetime.

Shearing Mechanism(Hydraulic Shearing Machine)

Advanced hydraulic drive, automatic punching and cutting after forming, no distorting or wasting, high level safety factor.

Blade Material : Cr12 quenched

Cutting system : All automatic

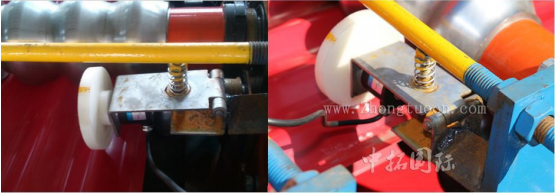

Counter

One counter gauges length, pulses, and decides length. Omron encoder for length measurement.

Products receiving tables

1. It adopts welded steel and supported roller to transmit the products.

2. 3*0.9*0.6m

Control device

1.Adopted PLC, transducer, touch panel from Delta Taiwan to ensure high speed with

stability, precision and lifetime.

2.Other electric element are Delta

3.Equipped with movable switch, air break, radiator, transformer & electric leakage protector for operation convenience and safety.

| Remarks |

| Payment terms | 30% T/T in advance and balance 70% after inspection confirmation before shipment. |

| Delivery | within 45 working days after receipt of deposit. |

| Packing | Nude packing with 1*40GP container |

| Warranty | One year, and we will provide the technical support for the whole life. |

| Installation | 1.Training: the buyer should charge of visa, return ticket, food and accommodation overseas and USD50/person/day for salary. 2. Need one technician 3. Training time: one week (contains the time of installation and adjustment) |

Looking for ideal Steel Sheet Roof Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Sheet Roof Panel Machine are quality guaranteed. We are China Origin Factory of Steel Panel Forming Machine. If you have any question, please feel free to contact us.

Product Categories : Roofing Sheet Roll Forming Machine > Roof and Wall Panel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu