Product Description

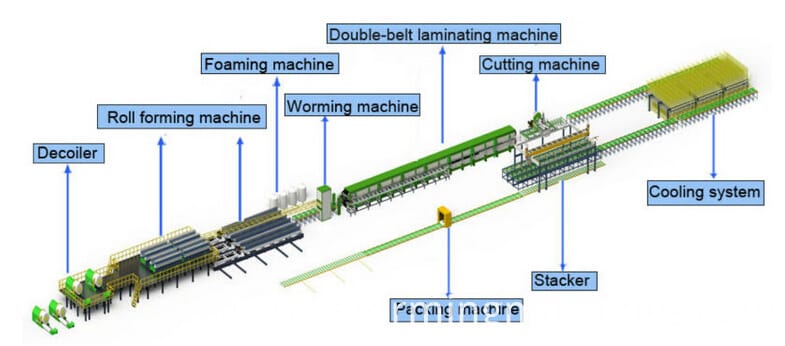

This Sandwich Panel roof forming machine include Decoiler, Laminating machine, roll forming system, forming machine, foaming part, Double-belt lamination machine,cutting part,

cooling system,stack,packing machine.

Sandwich panel will be a new materials for wall which is good for insulation, heat insulation,waterproof, lightweight.It is widely used in high-rise office buildings and high walls enclosing and decorative, industrial plants, cold storage, and insulation containers, etc.

The production Process of sandwich panel roof forming machine

Decoiler--- Laminating machine(cutting)---Roll Forming Machine---Worming machine--- Foaming machine---Double-belt laminating machine---Cutting part---Cooling system---stack and packing

Details of Sandwich Panel Production Line

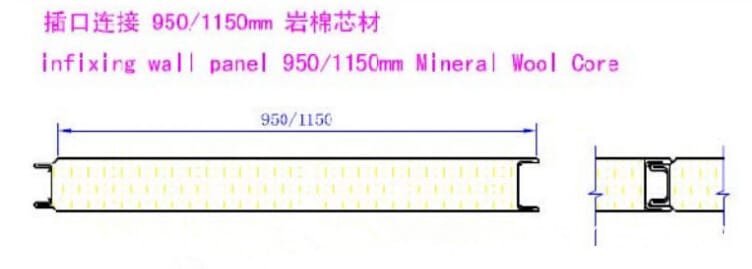

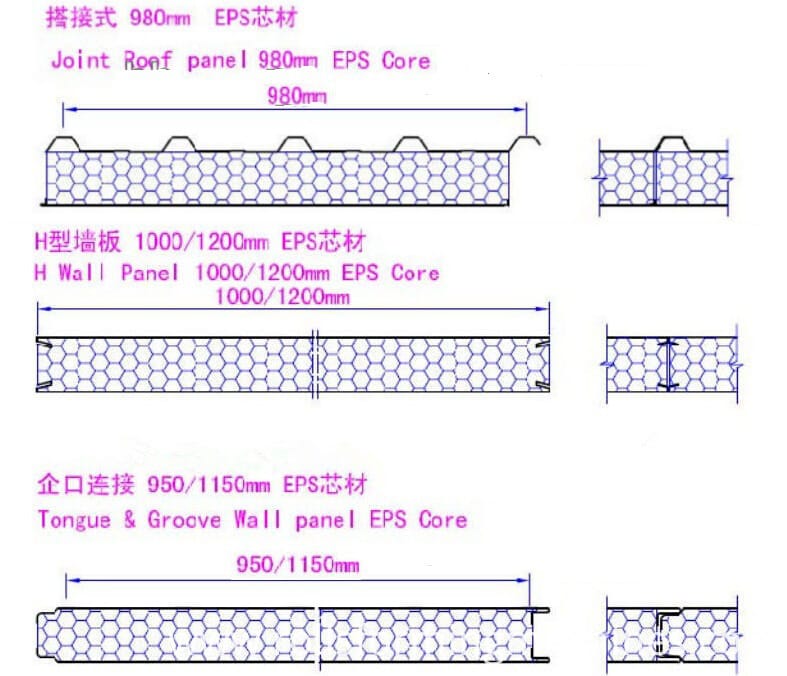

Panel showing :

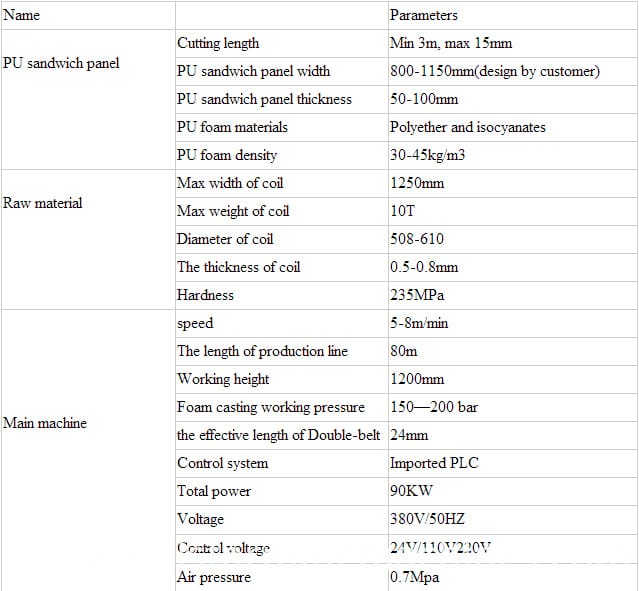

Parameters of sandwich panel roof forming machine

Looking for ideal Sandwich Panel Roof Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Sandwich Panel Roof Forming Machine are quality guaranteed. We are China Origin Factory of

Sandwich Panel Machine. If you have any question, please feel free to contact us.

Product Categories : Sandwich Panel Roll Forming Machine

Mr. Cary xu

Mr. Cary xu