Interlocked Oval Pipe Making Machine Middle Plate Frame

Main introduction of oval interlocked pipe making machine:

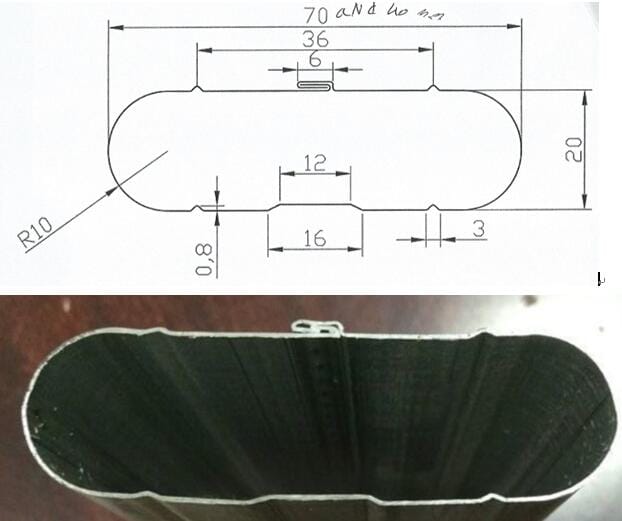

This production line is mainly used to make oval shape pipe by cold roll forming principle. And as to the seam, we take interlock technology. Here is the machine picture for your reference and the drawing profile & finishes product picture.

Basic parameter of this Welded Tube Mill Line for reference:

Thickness : From 0 .5 - 1.2mm

Length : 70 and 40mm for 2 sizes in one machine

Machine working process:

Decoiler-Feeding-Leveling-Roll Forming--Cutting--Product Table

Elements: Manual Decoiler, leveling beach, main Roll Forming Machine, shearing system, hydraulic station, PLC control station and runout table.

Each part introduction

Decoiler

Expanding method: Manual expanded version. ID:450-500mm OD:1200MM

Max loading:3 Ton Max width:300mm

Leveling beach of this kind of roll forming machine

Four rollers leveling beach to make sure material neat, clear and straight.

Rolling machine

1.Roller station:20stations

2.Shaft material:45# steel Outer diameter:50mm

3.Roller material: GCr15 quenching at 58 to 60 degree

4.Transport: Chain

5.Forming Speed: 0-8m/min

6.Motor:5.5kw

7.Machine :8.5mx0.8mx1.45m

8.Machine frame: 280 H beam

9. Frame thickness: 20mm, middle plate frame

9.Voltage:380v,50Hz,3 phase or csutomer

Flying cutting saw

1) Flying and tracking cutting saw, the cutting saw will adjust the cutting speed and location according to the main machine speed. By this method, the machine working speed will be same as the main machine accordingly. The cutting plate we take the best material for cutting it in high speed and beautiful cutting scare.

2) The material of blade: Cr12Mov, Hardening HRC 58-62℃

3)Length Tolerance:3m±1.5mm

4) Flying cutting saw, can make sure the perfect shape after shearing.

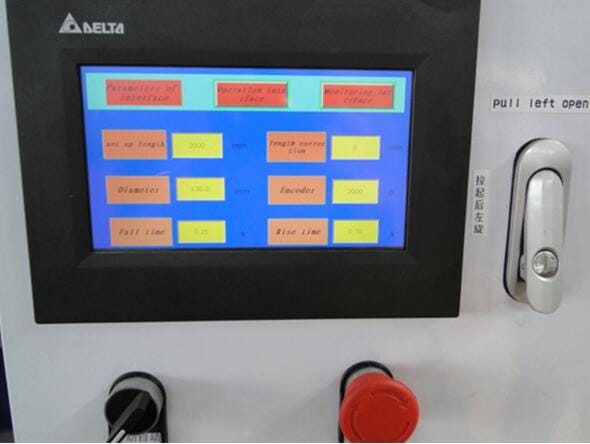

PLC Control

1.Screen: touch screen

2.PLC: Delta

3.Automatic-length measurement

4.Automatic-quantity measurement

5. Computer is used to control length and quantity. Machine will automatically cut to length and stop when required quantity is achieved

Length inaccuracy can be amended easily

Hydraulic System

1).Advanced hydraulic system from Taiwan

2). Power:3kw

Output frame

Could be welded locally according to customer needs.

Spare Parts

1).Easy damaged parts: conk 2 pcs, fuse-link 4 pcs

2).Rubber mat 1 pcs; Bolt spanner 1 pcs.

Warranty

1). One year, and we will provide the technical support for the whole life.

2).Training: the buyer should charge of visa, return ticket, food and

Accommodation overseas and USD50/person/day for salary.

3). Need one technicians

4).Training time: one week (contains the time of installation and adjustment)

Advantage of middle plate frame oval pipe making machine:

1. One machine supports many sizes and no need to change the mould of roll forming.

2. Middle plate frame, the machine cost will be quite lower.

3. Good after sell service.

If you are interested in other Spiral Welded Tube Machine, please feel free to contact with us.

Looking for ideal Oval Pipe Machine Manufacturer & supplier ? We have a wide selection at great prices to help you get creative. All the Interloacked Pipe Machine are quality guaranteed. We are China Origin Factory of Pipe Making Machine. If you have any question, please feel free to contact us.

Product Categories : Welded Tube Mill > Welded Pipe Machine

Mr. Cary xu

Mr. Cary xu